Sawmill servicing: Everything you need to know

The backbone of Zimbabwe’s long-standing timber industry is the humble sawmill. This machine is the unsung hero of our forestry and construction sectors, turning felled trees into usable timber. However, like any other laborious machine, even the most powerful sawmill requires regular servicing to maintain optimal performance, maximise uptime, and ensure durability.

Cutting Edge is Zimbabwe’s supplier of Wood-Mizer sawmills and spare parts. We understand how important proper maintenance is to your business. This thorough guide to sawmill maintenance gives you the knowledge you need to keep your business running smoothly.

The impact of proper sawmill servicing

Frequent servicing is an investment in your future profits. Did you know that proper maintenance can increase the lifespan of your sawmill by up to 30%, saving you thousands of dollars in future replacements? In addition, unscheduled downtime caused by malfunctions can cost Zimbabwean sawmills an average of $500 per hour. By proactively correcting small issues through regular servicing, you reduce downtime and increase your productive hours.

The benefits go far beyond financial rewards. Regular servicing promotes a safer workplace by identifying and correcting possible risks before they become a problem. Well-maintained machines also run more effectively, producing higher-quality timber with less waste, increasing total productivity and profitability.

What does a sawmill service entail?

The specific requirements of the service will vary according to your Wood-Mizer model and usage. However, some important things to focus on include:

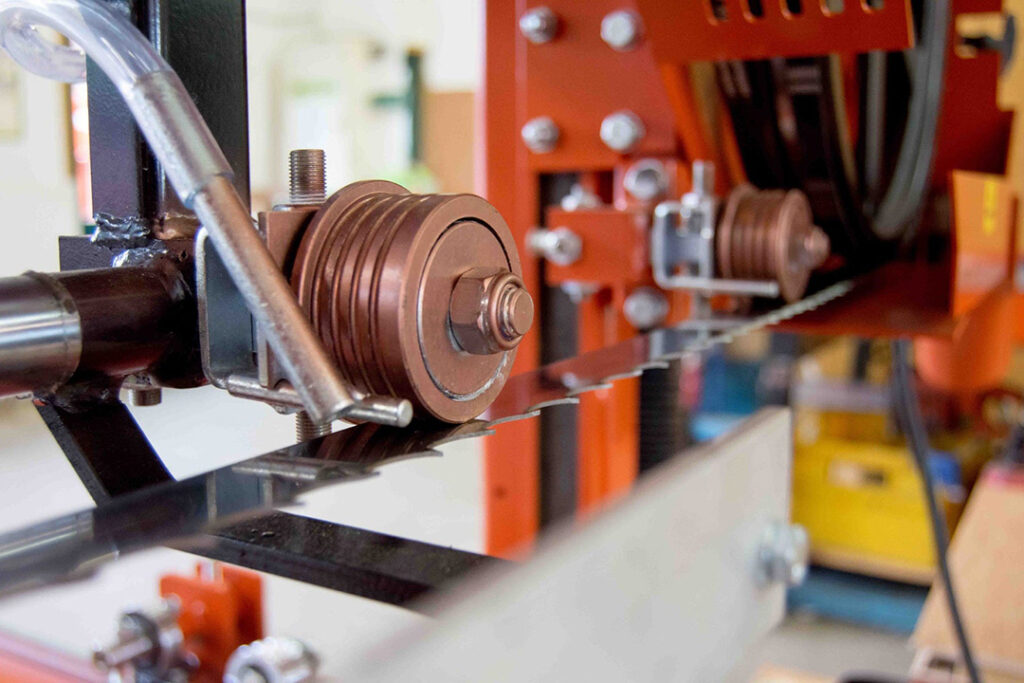

- Visual inspection – A keen eye can detect symptoms of wear and tear, leaks, loose parts, and possible damage before they become major issues. Check the condition of the chains responsible for forward/reverse and up/down movement of the head. Inspect the overall condition of rollers, wear of the collar, depth of grooves and the condition of bearings.

- Cleaning and lubrication – Removing sawdust, debris, and grime promotes smooth operation and reduces overheating. Regular lubrication ensures that vital components move without friction. Look closely at the rod shield found on the main frame. Check if the felt placed inside is sufficiently greased and if the condition of plastic sawdust scrapers on the main rod allows the machine to work properly.

- Blade maintenance – Sharpening, tensioning, and cleaning your blades at the recommended intervals ensures optimal cutting performance while reducing timber waste. Remember to check the deflection of the blade guide rollers on the blade.

- Belt and chain adjustments – Checking tension and wear, then making necessary changes or replacements, promotes efficient power transmission and eliminates slippage. Check the condition and the tension of the drive belts and adjust the tension or replace them with new belts if necessary.

- Fluid checks and filter replacements – Maintaining engine oil, hydraulic fluid, and coolant levels, as well as changing filters regularly, keeps your engine and hydraulic system functioning smoothly. Check the oil level and the condition of the filter in the hydraulic system (we recommend replacing the filter every 600 hours of sawmilling). If your sawmill has a battery, check the battery, its charging level, as well as the tension of the alternator belt and the condition of carbon brushes in the DC motors.

Beyond servicing: proactive maintenance tips

Remember, prevention is always better than a cure. Always invest in high-quality blades for precise cuts, extended durability and safety. Avoid overloading your sawmill to prevent unnecessary strain on the engine and components, as well as to minimise potential damage to the frame.

Always keep a clean and clear work environment. Remove offcuts from around the sawmill to prevent tripping hazards and clear away sawdust often to reduce wear and tear on your sawmill. Lastly, remember to keep detailed records of your service schedules, parts replacements and any other observations as this information will help you make better decisions in the future.

Finding a trusted partner for sawmill maintenance

Before servicing a sawmill, it’s important to find an authorised Wood-Mizer partner in Zimbabwe. Cutting Edge and our local network of dealers in the eastern Highlands sell high-quality sawmills and Wood-Mizer spare parts. We are committed to your long-term success and provide comprehensive sawmill servicing solutions.

We provide a large range of genuine Wood-Mizer components, ensuring optimum compatibility and performance for your exact model. Our highly educated and certified personnel have extensive experience with Wood-Mizer sawmills and are prepared to tackle any maintenance task with precision and efficiency.

By servicing your sawmill often, you invest in its potential to earn money. Wood-Mizer offers a winning formula for success in the Zimbabwean timber industry. Whether you need sawmills or spare parts, Cutting Edge and our network of approved dealers offer the knowledge and products to help you with your forestry projects. Contact us today to learn more about our forestry tools.

___

Cutting Edge is the leading supplier of Husqvarna products in Zimbabwe. We bring you the best tools in the business with world-class service and after sales care. Follow us on Facebook and Instagram for the latest news and product offerings from our brands.